Giant Kleinbottle -- Kingbridge Centre

In conjunction with Toronto's Kingbridge Centre and Killdee Scientific Glass, Acme Klein Bottle has finished the world's largest glass Klein Bottle. Scroll down for more photos!

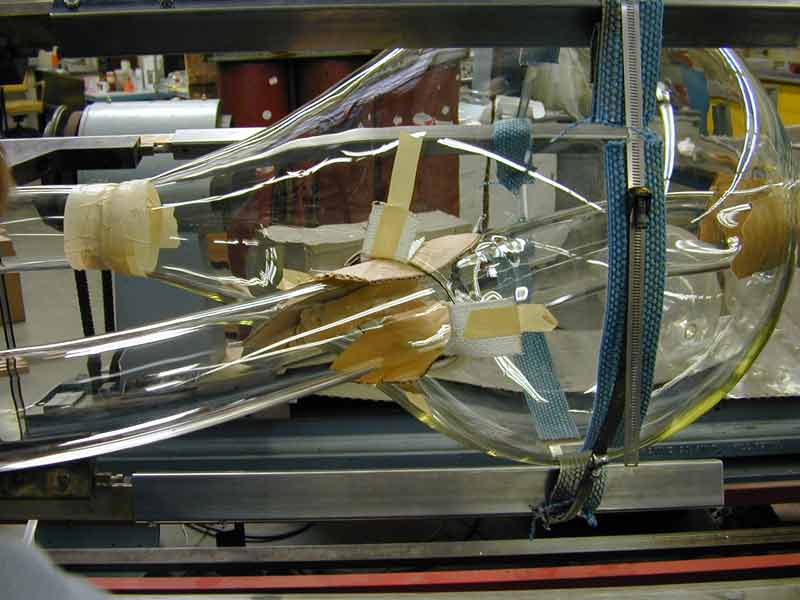

The Kingbridge Klein Bottle is 1.1 meter tall, 50. cm diameter, and is made of 15 Kg of clear Pyrex glass. (For non-scientists, that's 42 inches tall, 20 inches across, and 35 pounds)

With 6mm thick walls, it has the same smooth shape as Acme's Classical Klein Bottle. One sided, boundless, and mathematically nonorientable. It tickles topologists and amazes visitors.

It's the size of a 5 year old child. A ferret can climb "into" it.

It's been a nontrivial glassblowing project. Indeed, very few glassblowing shops could handle this job. (One glass blower said, "Too scary for us!")

Under the direction of Bob Maiden, Killdee Scientific Glass has built this giant Klein Bottle from Pyrex and Duran Borosilicate tubing. Much of the work involved building specialized torches and shaping jig. Because of its size, Bob and his assistants had to carefully coordinate their hand motions and machine operations in a high temperature dance of glass.

To make the top tube, we used 24 special oxy-acetylene torches to heat 90 mm Pyrex tubing red hot. We then bent a near-hairpin curve in the glass pipe. The main, pear-shaped flask is blown from a 72 litre Pyrex blank, using a special, wide-swing glass lathe. The curved pieces must be welded to a precision of a millimeter -- all the while wearing flameproof aluminum pyrosuits. After assembling, welding, and firepolishing, the Klein Bottle gets annealed at 1200 degrees F, to relieve internal stress.

Mathematically, this is identical to our smaller Klein Bottles -- that is, topology does not care about changes in size. It's bigger than your average boundless thing.

This is a Giant Klein Bottle, resulting in a delightful German oxymoron, RiesenKLEINflasche (Many thanks to Georg Moritz of Stuttgart-Korntal for helping make such a flavorful play on words!)

To a mathematician, it's a one-sided bottle, homeomorphic to a disc with two crosscaps. To a glass worker, it's a major challenge in glassblowing. To the casual viewer, it's an accomplishment in art, glass, and mathematics.

We've spun the main flask from a 50 litre blank. Enough heat to melt part of the chuck on the lathe... See photos at bottom of page.

The question mark tubing section uses six foot lengths of 90mm diameter tubing. The tubing is so heavy and unweildy that we're doing this in three heats. We successfully bent the 90mm tubing in the first heat.

From the Kingbridge Centre press release:

The Kingbridge Centre is is located in King City, just north of Toronto. Five bridges interconnect the conference centre (we're not quite sure why there are so many), so the "bridge" part of the name is relevant to what a conference center is all about.

Bridges connect locations. Conferences connect people, ideas, organizations. Bridges can be short, long, big, small, simple, temporary, complicated, basic, innovative. Everywhere you look, there is an opportunity to build a bridge.

The Kingbridge Centre has adopted a stylized, partial representation of a Klein Bottle...a bridge of a different kind. The Klein bottle is a mathematical construct that shows a continuous surface with only one side(the "true" version only exists in four dimensions!) In other words, the inside and the outside are the same. It's an unusual bridge...and definitely the type of "outside the box" thinking we encourage at Kingbridge!

Go to Acme's Klein Bottle's Home Page

Photos of the construction of this giant Klein Bottle:

|

Heating the tubing over the surface burners. |

|

Bending 90mm tubing. To avoid kinks, we inflate the pipe while bending. These are special home-built surface burners, unlike any used by glassblowers. Ordinary torches don't provide enough heat to bend this tubing. |

|

90 mm tubing bending on shaping jig for top bend. it's HOT! |

|

Testing the torch with "small" 2 inch diameter tubing. This is an experiment to get the choreography correct. Notice the blow-tube to pressurize the pipe during the bend - without internal pressure, the tubing would kink. |

|

The finished bend for the 2 inch tubing test. |

|

Top Bend for finished 90 mm tubing. Hooray! |

|

Top bend for finished 90 mm tubing. Next comes the bottom bend.... |